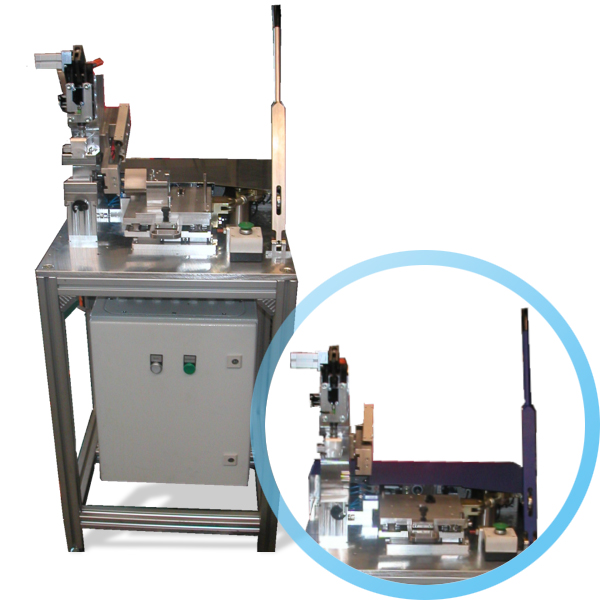

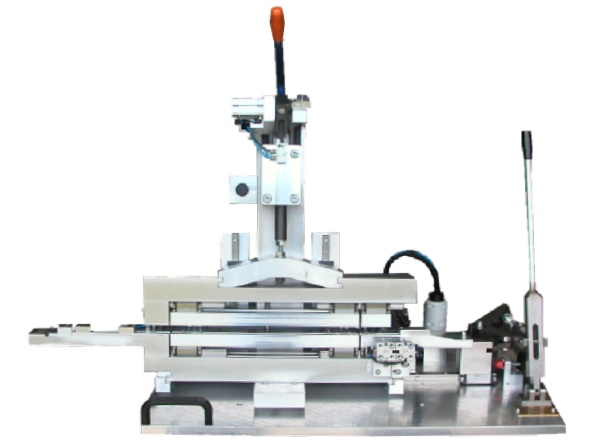

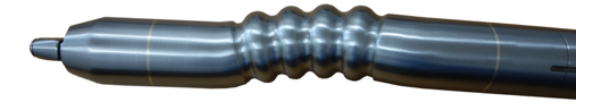

Gauges are used for testing the geometry of pipes, hoses and other components for the automotive industry.

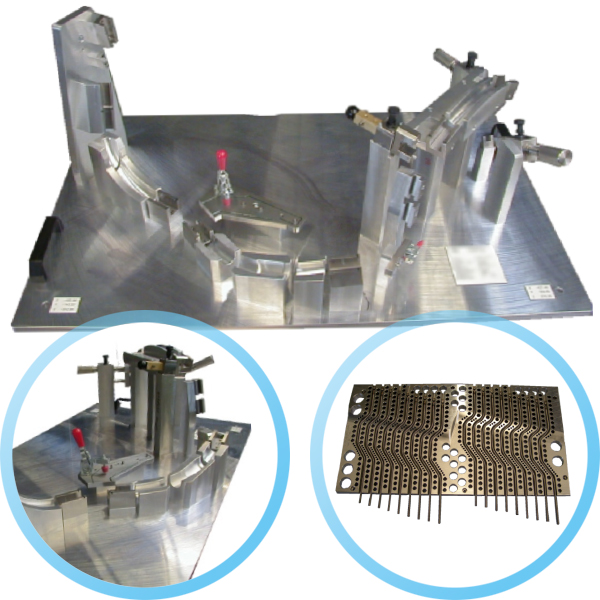

The test gauges shown here allow the testing of fully assembled cables. Depending on the requirement, the gauges can be made of aluminium, plastic or other materials.

In accordance with our customers’ specifications we create a 3D model for each gauge required. After production, which requires the highest level of accuracy, we measure the gauges and the measuring data is recorded. A 3D measuring arm with special software is used for this precise measurement. During the measuring process, the measurements are compared immediately with the target values of the 3D CAD models of the gauge. At the end of the measuring process a detailed measuring record is issued and shows whether all measurements are within the tolerance zone.

Customers